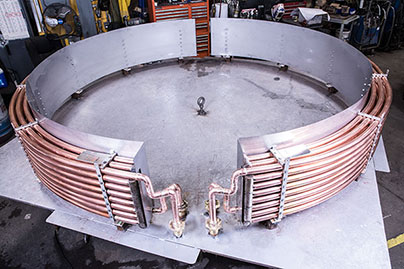

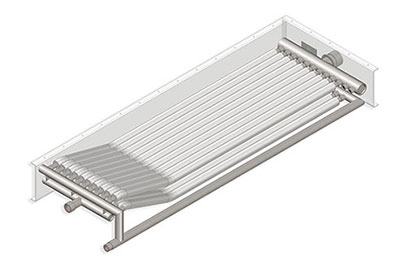

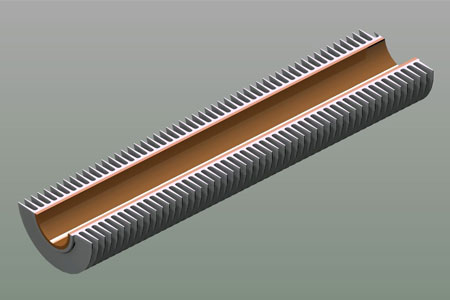

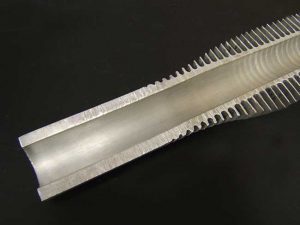

At the heart of most Thermofin heat exchanger’s technology, like in our famous line of generator and motor coolers, lies Thermofin’s aluminum extruded finned tubes, the lead actors on which rests the efficiency and longevity of our units. Their particular design, mono or bimetal, provides great resistance (fin stiffness) as well as exceptional heat transfer characteristics (longevity, temperature, range, etc.). The mechanical bond joining liner tubes and aluminum wall offers superior durability and insures no corrosion occurs between the fins and the tubes, a key factor in permitting the delivery of the specified duty by your heat exchanger. Extend the lifetime of your exchangers and improve their efficiency and reliability by combining them with the best technology, the POWERFIN extruded finned tubes.

WHY USE FINS?

Generally, tubes equipped with surface enhancing devices, such as fins or grooves, are used where heat exchange is required between two fluids whose ability to transmit calories is very far apart. For a water / air exchange, for example, the local exchange coefficient on the water side is much higher than that on the air side. Thus, fins are added to the surface in contact with air in order to increase the density of the heat flux between the two fluids.

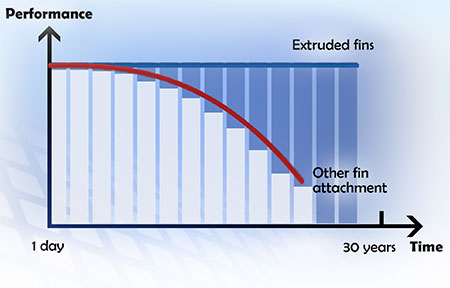

Being the only interface between the hot and cold source, the extruded finned tube is at the heart of heat transfer. Its quality plays a key role in the ability of an exchanger to efficiently transfer thermal energy between the two fluids. More precisely, the way in which the fin is secured to the tube affects the efficiency of the exchanger in the short, medium and long term.

Indeed, studies have shown that the main cause of the loss of efficiency of an exchanger is due to a loss of quality of the fin attachment to the tube. Indeed, after a few thermal cycle, a gap between the fins and the tubes occurs due to thermal expansion and vibrations. Galvanic corrosion between the two materials is also negatively affecting the tube-to-fin bond.

PERFORMANCE - THE BENEFITS OF EXTRUDED ALUMINUM

The performance degradation of a heat exchanger is essentially due to two phenomenons which occurs over time :

- Increased fouling resistance due to impurity accumulation contained in both fluids.

- Increased thermal resistance at the tube-to-fin bond due to thermal cycling dilatation of the materials and to corrosion at the fin base or root. These factors creates a loss of contact or bond pressure in between the fins and the tube.

HOW TO PREVENT LOSS OF PERFORMANCE?

- Fouling impact on heat exchanger performance can be reduced by an internal and external cleaning on a regular basis.

- There is No remedial solution (except tube replacement) for correcting performance degradation due to increased tube-to-fin resistance but this can be prevented by using aluminum extruded finned tubes.

USE ALUMINUM EXTRUDED FINS!

How POWERFIN aluminum extruded finned tubes prevent loss of performance due to tube-to-fin bond resistance?

Because the aluminum completely encloses the tube material!

- No gap between fins

- No possibility of contaminant accumulation underneath the fins

- No possibility of corrosion in between fins and tubes

PRODUCTION STANDARD

Thermofin offers, as a standard, a wide range of extruded finned tubes. The inner tube material, tube diameter, fin diameter and fin spacing are the main parameters to take into account. The inner tube is generally made out from copper nickel, copper, stainless steel or carbon steel but, thanks to extruded fin technology, there is no restriction and any material can be used for the inner tube. Suitable materials will be selected depending on your process conditions. Aluminum, admiralty brass, titanium, monel or hastelloy are some examples of the material which can be used. Here is a list of Thermofin’s extruded finned tube standard

- Tubes diameter

- 3/8″ (9.52 mm)

- 5/8″ (15.9 mm)

- 3/4″ (19 mm)

- 7/8″ (22.2 mm)

- 1″ (25.4 mm)

- 1.05″ (26.7 mm)

- 1.315″ (33.4 mm)

- 1 1/2″ (38.1 mm)

- Fins diameter

- 1.1″ (28 mm)

- 1 3/8″ (35 mm)

- 1 1/2″ (38.1 mm)

- 1 3/4″ (44.5 mm)

- 1 7/8″ (47.6 mm)

- 2″ (50.8 mm)

- 2 1/4″ (57.2 mm)

- 2.315″ (58.8 mm)

- 2 1/2″ (63.5 mm)

- Fins spacing (fins per inch)

- 4 fpi (157 fin/m)

- 5 fpi (197 fin/m)

- 7 fpi (276 fin/m)

- 8 fpi (315 fin/m)

- 9 fpi (354 fin/m)

- 10 fpi (393 fin/m)

- 11 fpi (433 fin/m)

- 14 fpi (551 fin/m)

- 16 fpi (630 fin/m)

OPTIONS & SERVICES

MONO-ALUMINIUM

With its extensive experience, Thermofin has developed mono-aluminum finned tubes (one piece extruded finned tubes, without any inner tubes) for specific application such viscous fluid cooling, heat recovery with heat pipes or for application where weight might be an issue (very light heat exchanger with full aluminum construction)

HEAT PIPES

Based on Thermofin’s extruded fin tube technology, our selection of heat pipes is designed to suit the need of the Original Equipment Manufacturer. Whether they’re bent in “U” shape or equipped with end fitting to facilitate their filling, Thermofin’s heat pipe designs are devoted to match your thermal and geometrical requirements. Their superior thermal performance is partly linked to the fintube inside capillary surface. Created during the tube manufacture, this surface promotes the refrigerant migration.

CUSTOMIZATION

Thermofin can create specific finned tubes for your needs like intergral turbulator finned tubes or double tube construction finned tubes.

THE THERMOFIN BENEFIT

You are an agent interested in selling our products, or you are simply looking for additional information? Don’t hesitate to download our brochures. We can also provide, upon request, prints & other promotional material.